The Energy Efficient New Variable Frequency Vulcanizing Machines of Doublestar Machinery

The equipment not only inherits the advantages of the mechanical vulcanizing machine with convenient operation and easy maintenance, but also gives attention to the advantages of the hydraulic vulcanizing machine with high precision and good stability, which takes PLC as the control core and uses industrial computer man-machine interactive interface, making the real-time collection, storage and alarm of the parameters, energy consumption monitoring and vulcanizing mould fault detection during the vulcanization process realizable, and supporting the vulcanizing machine cluster network and other related functions.

With the characteristics of energy efficiency, stability, reliability, accurate positioning, convenient production shift and easy maintenance, the equipment can be seamlessly connected with the 4.0 automatic tire factories, and plays an important role in promoting the transformation and upgrading of the tire industry.

Compared with the traditional mechanical vulcanizing machine, the mechanical-hydraulic mixed variable frequency vulcanizing machine has four technical advantages, including hydraulic system replacing power water, variable frequency technology for tire loading mechanism, new central mechanism and hot plate with large mazy cavity. Its main characteristics include:

Energy efficiency: It uses hydraulic drive instead of power water with short auxiliary time and can save water resources.

Stability & reliability: With variable speed drive, there is no impact; no power water, leakage, string of water or loss of pressure problems; it can realize internal temperature measurement in central mechanism with accurate temperature measurement.

Accurate positioning: With variable frequency manipulator, the roll-in and roll-out positioning accuracy ≤ 0.5mm; with new central mechanism, the lifting positioning accuracy of upper ring ±1.5mm.

Convenient production shift: It doesn’t need to remove the central mechanism to replace the copper sleeve for production shift.

Easy maintenance: With more reliable hydraulic seal, it takes 3~5 years to replace the seal.

In addition, the whole cycle time of the variable frequency vulcanizing machine ≤ 210 seconds; with uniform temperature on the surface of the hot plate, the temperature difference ≤±1℃, and the cylinder head of the central mechanism adopts the side screw steam injection structure design, so the inside temperature of the capsule is uniform; and the temperature difference measured by capsule embedding line ≤ 5℃.

It is understood that Doublestar Machinery has began to develop this variable frequency vulcanizing machine since 2015. In 2016, the first generation product was officially put into production in Qingdao Doublestar Tire Industrial Co., Ltd. After production verification, the equipment is stable in use, energy saving and efficient. Since then, the technical team of the company has kept improving and optimizing the equipment and has provided high-quality services for Bayi Rubber Co., Ltd., Double Coin Group (Xinjiang) Kunlun Tire Co., Ltd. and other tire manufacturers. It not only saves RMB 8,000 Yuan/set a year for the users and is widely recognized by the users, but also provides a production case for new customers to choose a variable frequency vulcanizing machine.

Zimbabwean Client Visits KELUCK TYRE, Forges New Partnership

Zimbabwean Client Visits KELUCK TYRE, Forges New Partnership

Season’s Greetings from QINGDAO KELUCK TYRE CO., LTD.

Season’s Greetings from QINGDAO KELUCK TYRE CO., LTD.

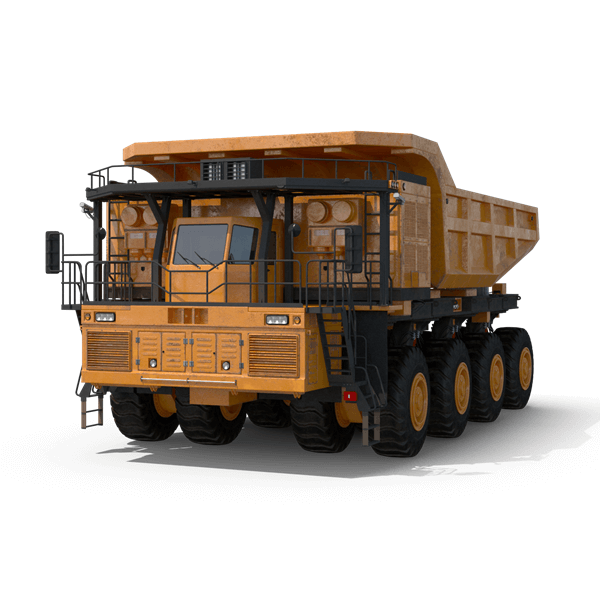

**ROADSTAR Launches R516 Pattern, a Robust Tire Solution for Mining Applications**

**ROADSTAR Launches R516 Pattern, a Robust Tire Solution for Mining Applications**

KELUCK TYRE Solid OTR Tires Successfully Enter the European Market, Gaining Acclaim in Belgium

KELUCK TYRE Solid OTR Tires Successfully Enter the European Market, Gaining Acclaim in Belgium