YATONE HP/UHP TYRE P308 Pattern

Brand Name: YATONE

Type: Radial Car Tyre

MOQ: Mixed sizes total 1x20ft container

Size: 205/55R16 215/35R18 215/40R17 215/45R16 215/45R17 215/50R17 215/55R16 215/55R17 215/60R16

P308

UP/UHP CAR TYRE

Asymmetri Tread Pattern-Inside

Stable outer shoulder for optional handling day conditions and braking characteristics.

Asymmetri Tread Pattern-outsider/ Enclosed shoulder block for every wear and reduce noise.

Central vertical Rib/ Central rib guarantee the high-speed stability/ Compound design

| Max load(KG) | Max load(LBS) | Tread depth | Quantity/40' HQ | UTQG | Label grade | ||||||||

| Size | Category | Load index | Speed symbol | Single | Single | (MM) | no packing | Tread wear | Traction | Temperature | rolling resistance | Wet grip | Noise(dB) |

| 155/65R13 | HP | 73 | T | 365 | 805 | 7.4 | 2470 | 400 | A | A | E | B | 70 |

| 155/65R14 | HP | 75 | T | 387 | 853 | 7.4 | 1750 | 400 | A | A | E | E | 70 |

| 155/70R13 | HP | 75 | T | 387 | 853 | 7.4 | 2200 | 400 | A | A | E | E | 70 |

| 155/80R13 | HP | 79 | T | 437 | 963 | 7.4 | 1650 | 400 | A | A | E | E | 70 |

| 165/60R14 | HP | 75 | H | 387 | 853 | 7.4 | 1900 | 400 | A | A | E | E | 70 |

| 165/65R13 | HP | 77 | T | 412 | 908 | 7.4 | 1960 | 400 | A | A | E | B | 70 |

| 165/70R13 | HP | 79 | T | 437 | 963 | 7.4 | 1900 | 400 | A | A | E | B | 70 |

| 165/70R14 | HP | 81 | T | 462 | 1019 | 7.4 | 1850 | 400 | A | A | E | B | 70 |

| 165/70R14 | HP | 85 | T | 515 | 1135 | 7.4 | 1850 | 400 | A | A | E | B | 70 |

| 175/60R13 | HP | 77 | T | 412 | 908 | 7.4 | 1750 | 400 | A | A | C | C | 70 |

| 175/65R13 | HP | 80 | T | 450 | 992 | 7.4 | 1700 | 400 | A | A | E | B | 70 |

| 175/65R14 | HP | 82 | H | 475 | 1047 | 7.6 | 1810 | 400 | A | A | E | B | 70 |

| 175/65R14 | HP | 82 | T | 475 | 1047 | 7.6 | 1810 | 400 | A | A | E | B | 70 |

| 175/65R15 | HP | 84 | H | 500 | 1102 | 7.6 | 1500 | 400 | A | A | C | B | 70 |

| 175/70R13 | HP | 82 | T | 475 | 1047 | 7.4 | 1800 | 400 | A | A | E | B | 70 |

| 175/70R14 | HP | 84 | H | 500 | 1102 | 7.4 | 1750 | 400 | A | A | C | B | 70 |

| 175/70R14 | HP | 88 | H | 560 | 1235 | 7.4 | 1750 | 400 | A | A | C | B | 70 |

| 185/50R16 | HP | 85 | V | 515 | 1135 | 7.6 | 1400 | 400 | A | A | E | B | 70 |

| 185/55R15 | HP | 82 | V | 475 | 1047 | 7.6 | 1320 | 400 | A | A | E | B | 70 |

| 185/55R16 | HP | 87 | V | 545 | 1201 | 7.6 | 1350 | 400 | A | A | E | B | 70 |

| 185/60R14 | HP | 82 | H | 475 | 1047 | 7.6 | 1512 | 400 | A | A | E | B | 70 |

| 185/60R15 | HP | 84 | H | 500 | 1102 | 7.6 | 1300 | 400 | A | A | E | B | 70 |

| 185/60R15 | HP | 88 | H | 560 | 1235 | 7.6 | 1300 | 400 | A | A | C | B | 70 |

| 185/65R14 | HP | 86 | H | 530 | 1168 | 7.6 | 1470 | 400 | A | A | E | B | 70 |

| 185/65R14 | HP | 86 | T | 530 | 1168 | 7.6 | 1470 | 400 | A | A | E | B | 70 |

| 185/65R15 | HP | 88 | H | 560 | 1235 | 7.6 | 1410 | 400 | A | A | C | B | 70 |

| 185/70R13 | HP | 86 | H | 530 | 1168 | 7.6 | 1700 | 400 | A | A | C | C | 70 |

| 185/70R13 | HP | 86 | T | 530 | 1168 | 7.6 | 1700 | 400 | A | A | C | C | 70 |

| 185/70R14 | HP | 88 | T | 560 | 1235 | 7.6 | 1490 | 400 | A | A | C | B | 70 |

| 195/45R16 | UHP | 84 | V | 500 | 1102 | 7.8 | 1200 | 400 | A | A | E | B | 71 |

| 195/50R15 | HP | 82 | V | 475 | 1047 | 7.8 | 1430 | 400 | A | A | E | B | 71 |

| 195/50R16 | HP | 84 | V | 500 | 1102 | 7.8 | 1250 | 400 | A | A | C | C | 71 |

| 195/50R16 | HP | 88 | V | 560 | 1235 | 7.8 | 1250 | 400 | A | A | C | C | 71 |

| 195/55R15 | HP | 85 | H | 515 | 1135 | 7.8 | 1356 | 400 | A | A | E | B | 71 |

| 195/55R15 | HP | 85 | V | 515 | 1135 | 7.8 | 1356 | 400 | A | A | E | B | 71 |

| 195/55R16 | HP | 87 | V | 545 | 1201 | 7.8 | 1200 | 400 | A | A | E | B | 71 |

| 195/60R14 | HP | 86 | H | 530 | 1168 | 7.8 | 1200 | 400 | A | A | E | B | 71 |

| 195/60R15 | HP | 88 | H | 560 | 1235 | 7.8 | 1291 | 400 | A | A | C | B | 71 |

| 195/60R16 | HP | 89 | H | 580 | 1279 | 7.8 | 1300 | 400 | A | A | C | B | 71 |

| 195/65R15 | HP | 91 | H | 615 | 1356 | 7.8 | 1250 | 400 | A | A | E | B | 71 |

| 195/65R15 | HP | 91 | V | 615 | 1356 | 7.8 | 1250 | 400 | A | A | E | B | 71 |

| 195/70R14 | HP | 91 | H | 615 | 1356 | 7.8 | 1272 | 400 | A | A | C | B | 71 |

| 195/70R14 | HP | 91 | T | 615 | 1356 | 7.8 | 1272 | 400 | A | A | C | B | 71 |

| 205/40R17 | UHP | 84 | W | 500 | 1102 | 7.8 | 1280 | 400 | A | A | C | B | 71 |

| 205/45R16 | UHP | 87 | W | 545 | 1201 | 7.8 | 1100 | 400 | A | A | C | C | 71 |

| 205/45R17 | UHP | 84 | W | 500 | 1102 | 7.8 | 1163 | 400 | A | A | E | B | 71 |

| 205/45R17 | UHP | 88 | W | 560 | 1235 | 7.8 | 1163 | 400 | A | A | C | B | 71 |

| 205/50R16 | HP | 87 | W | 545 | 1201 | 7.8 | 1160 | 400 | A | A | E | B | 71 |

| 205/50R17 | HP | 93 | W | 650 | 1433 | 7.8 | 1070 | 400 | A | A | C | B | 71 |

| 205/55R16 | HP | 91 | V | 615 | 1356 | 7.8 | 1196 | 400 | A | A | C | B | 71 |

| 205/55R16 | HP | 91 | W | 615 | 1356 | 7.8 | 1196 | 400 | A | A | C | B | 71 |

| 205/55R16 | HP | 94 | W | 670 | 1477 | 7.8 | 1196 | 400 | A | A | C | B | 71 |

| 205/55R17 | HP | 95 | W | 690 | 1521 | 7.8 | 1000 | 400 | A | A | |||

| 205/60R14 | HP | 88 | T | 560 | 1235 | 7.8 | 1300 | 400 | A | A | C | C | 71 |

| 205/60R15 | HP | 91 | H | 615 | 1356 | 7.8 | 1148 | 400 | A | A | C | B | 71 |

| 205/60R16 | HP | 92 | H | 630 | 1389 | 7.8 | 1100 | 400 | A | A | C | B | 71 |

| 205/65R15 | HP | 94 | H | 670 | 1477 | 7.8 | 1170 | 400 | A | A | C | B | 71 |

| 205/70R14 | HP | 95 | T | 690 | 1521 | 7.6 | 1280 | 400 | A | A | C | B | 70 |

| 205/70R14 | HP | 98 | T | 750 | 1653 | 7.6 | 1280 | 400 | A | A | C | B | 71 |

| 205/70R15 | HP | 96 | H | 710 | 1565 | 7.8 | 950 | 400 | A | A | C | B | 71 |

| 215/35R18 | UHP | 84 | W | 500 | 1102 | 7.8 | 1180 | 400 | A | A | E | B | 71 |

| 215/40R17 | UHP | 87 | W | 545 | 1201 | 7.8 | 1100 | 400 | A | A | E | B | 71 |

| 215/45R16 | UHP | 90 | V | 600 | 1323 | 7.8 | 1200 | 400 | A | A | |||

| 215/45R17 | UHP | 91 | W | 615 | 1356 | 7.8 | 1040 | 400 | A | A | C | B | 71 |

| 215/50R17 | HP | 95 | W | 690 | 1521 | 7.8 | 1050 | 400 | A | A | C | B | 71 |

| 215/55R16 | HP | 97 | W | 730 | 1609 | 7.8 | 1040 | 400 | A | A | C | B | 71 |

| 215/55R17 | HP | 98 | W | 750 | 1653 | 7.8 | 924 | 400 | A | A | C | B | 71 |

| 215/60R16 | HP | 99 | H | 775 | 1709 | 8.1 | 952 | 400 | A | A | C | B | 71 |

| 215/65R15 | HP | 96 | H | 710 | 1565 | 7.8 | 950 | 400 | A | A | C | B | 71 |

| 215/70R15 | HP | 98 | H | 750 | 1653 | 7.8 | 920 | 400 | A | A | C | B | 71 |

| 225/35R19 | UHP | 88 | W | 560 | 1235 | 7.8 | 950 | 400 | A | A | E | C | 71 |

| 225/35R20 | UHP | 90 | W | 600 | 1323 | 8 | 840 | 400 | A | A | E | C | 71 |

| 225/40R18 | UHP | 92 | W | 630 | 1389 | 7.8 | 976 | 400 | A | A | E | C | 71 |

| 225/45R17 | UHP | 94 | W | 670 | 1477 | 7.8 | 988 | 400 | A | A | C | B | 71 |

| 225/45R18 | UHP | 95 | W | 690 | 1521 | 7.8 | 914 | 400 | A | A | C | B | 71 |

| 225/50R16 | HP | 96 | W | 710 | 1565 | 7.8 | 902 | 400 | A | A | C | C | 71 |

| 225/50R17 | HP | 98 | W | 750 | 1653 | 7.8 | 900 | 400 | A | A | C | C | 71 |

| 225/55R16 | HP | 95 | V | 690 | 1521 | 7.8 | 828 | 400 | A | A | E | C | 71 |

| 225/55R16 | HP | 99 | V | 775 | 1709 | 7.8 | 828 | 400 | A | A | C | C | 71 |

| 225/55R17 | HP | 101 | W | 825 | 1819 | 7.8 | 920 | 400 | A | A | C | C | 71 |

| 225/60R16 | HP | 98 | H | 750 | 1653 | 8.1 | 974 | 400 | A | A | C | B | 71 |

| 235/35R19 | UHP | 91 | W | 615 | 1356 | 7.8 | 850 | 400 | A | A | E | C | 71 |

| 235/40R18 | UHP | 95 | W | 690 | 1521 | 7.8 | 906 | 400 | A | A | E | C | 71 |

| 235/45R17 | UHP | 97 | W | 730 | 1609 | 7.8 | 900 | 400 | A | A | C | C | 71 |

| 235/45R18 | UHP | 98 | Y | 750 | 1653 | 7.8 | 850 | 400 | A | A | E | C | 71 |

| 235/50R17 | HP | 100 | W | 800 | 1764 | 8 | 850 | 400 | A | A | E | C | 71 |

| 235/50R18 | HP | 101 | W | 825 | 1819 | 8 | 780 | 400 | A | A | E | C | 71 |

| 235/55R17 | HP | 103 | W | 875 | 1929 | 7.8 | 850 | 400 | A | A | B | B | 71 |

| 245/35R19 | UHP | 93 | W | 650 | 1433 | 7.8 | 700 | 400 | A | A | E | C | 71 |

| 245/40R17 | UHP | 95 | W | 690 | 1521 | 7.8 | 850 | 400 | A | A | E | C | 71 |

| 245/40R18 | UHP | 97 | W | 730 | 1609 | 7.8 | 800 | 400 | A | A | E | C | 71 |

| 245/45R17 | UHP | 99 | W | 775 | 1709 | 7.8 | 800 | 400 | A | A | C | C | 71 |

| 245/45R18 | UHP | 100 | W | 800 | 1764 | 7.8 | 800 | 400 | A | A | C | C | 71 |

| 245/45R18 | UHP | 96 | W | 710 | 1565 | 7.8 | 800 | 400 | A | A | E | C | 71 |

| 245/45R20 | UHP | 99 | W | 775 | 1709 | 7.8 | 650 | 400 | A | A | E | C | 72 |

| 245/55R19 | HP | 103 | W | 875 | 1929 | 8 | 650 | 400 | A | A | E | C | 71 |

| 255/35R18 | UHP | 94 | W | 670 | 1477 | 7.8 | 780 | 400 | A | A | E | C | 72 |

| 255/35R19 | UHP | 96 | Y | 710 | 1565 | 7.8 | 770 | 400 | A | A | E | C | 73 |

| 255/35R20 | UHP | 97 | W | 730 | 1609 | 7.8 | 630 | 400 | A | A | E | C | 72 |

| 255/40R19 | UHP | 100 | W | 800 | 1764 | 8 | 750 | 400 | A | A | E | C | 72 |

| 255/45R18 | UHP | 103 | W | 875 | 1929 | 7.8 | 750 | 400 | A | A | C | C | 72 |

| 265/30R19 | UHP | 93 | W | 650 | 1433 | 7.8 | 560 | 400 | A | A | E | C | 72 |

| 265/45R20 | UHP | 104 | W | 900 | 1984 | 7.8 | 650 | 400 | A | A | |||

| 275/30R19 | UHP | 96 | W | 710 | 1565 | 7.8 | 510 | 400 | A | A | E | C | 72 |

| 275/40R20 | UHP | 106 | Y | 950 | 2094 | 7.8 | 630 | 400 | A | A | E | C | 73 |

| 275/45R20 | UHP | 110 | V | 1060 | 2337 | 8.7 | 580 | 400 | A | A | C | C | 72 |

| 275/55R20 | HP | 117 | W | 1285 | 2833 | 7.8 | 520 | 400 | A | A | C | C | 72 |

| 285/35R22 | UHP | 112 | W | 1120 | 2469 | 7.8 | 470 | 400 | A | A | E | C | 75 |

| 285/50R20 | HP | 116 | V | 1250 | 2756 | 8.7 | 500 | 400 | A | A | C | C | 74 |

| 305/35R24 | UHP | 112 | W | 1120 | 2469 | 7.8 | 400 | 400 | A | A | C | C | 75 |

| 315/35R20 | UHP | 110 | Y | 1060 | 2337 | 7.8 | 510 | 400 | A | A | |||

1. Kekucktyre is professional in tires production and export for more than 15 years.

2. Our factory covers an area of 0.6 million square meters, has over 2000 employees.

3. We have been exporting to more than 120 different countries and regions all over the world.

4. 120000-160000 running miles guarantee can be offered for Maxind Truck tires

5. Our tires are made of advanced German technology, using natural imported Malaysia rubber and BEKA steel.

6. We have a professional technical team with 50 experienced engineers.

7. We are Golden Supplier of Alibaba Group, and provide the customer with Trade Assurance.

8. Market promotion support and the best after-sales service will be offered to every customer and help them get more new customers and orders.

9. Exclusive representative acceptable.

10. Within 6 hours reply after getting your tire inquiry, and not let the customer wait for so long time.

Q1. What are your terms of packing?

A: This depends on customer requirements.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What are your terms of delivery?

A: FOB, CNF

Q4. How about your delivery time?

A: Generally, it will take 15 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples. but you need a cost sample and freight charge.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the freight cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have a 100% test before delivery

Q8: How do you make our business long-term and a good relationship?

1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

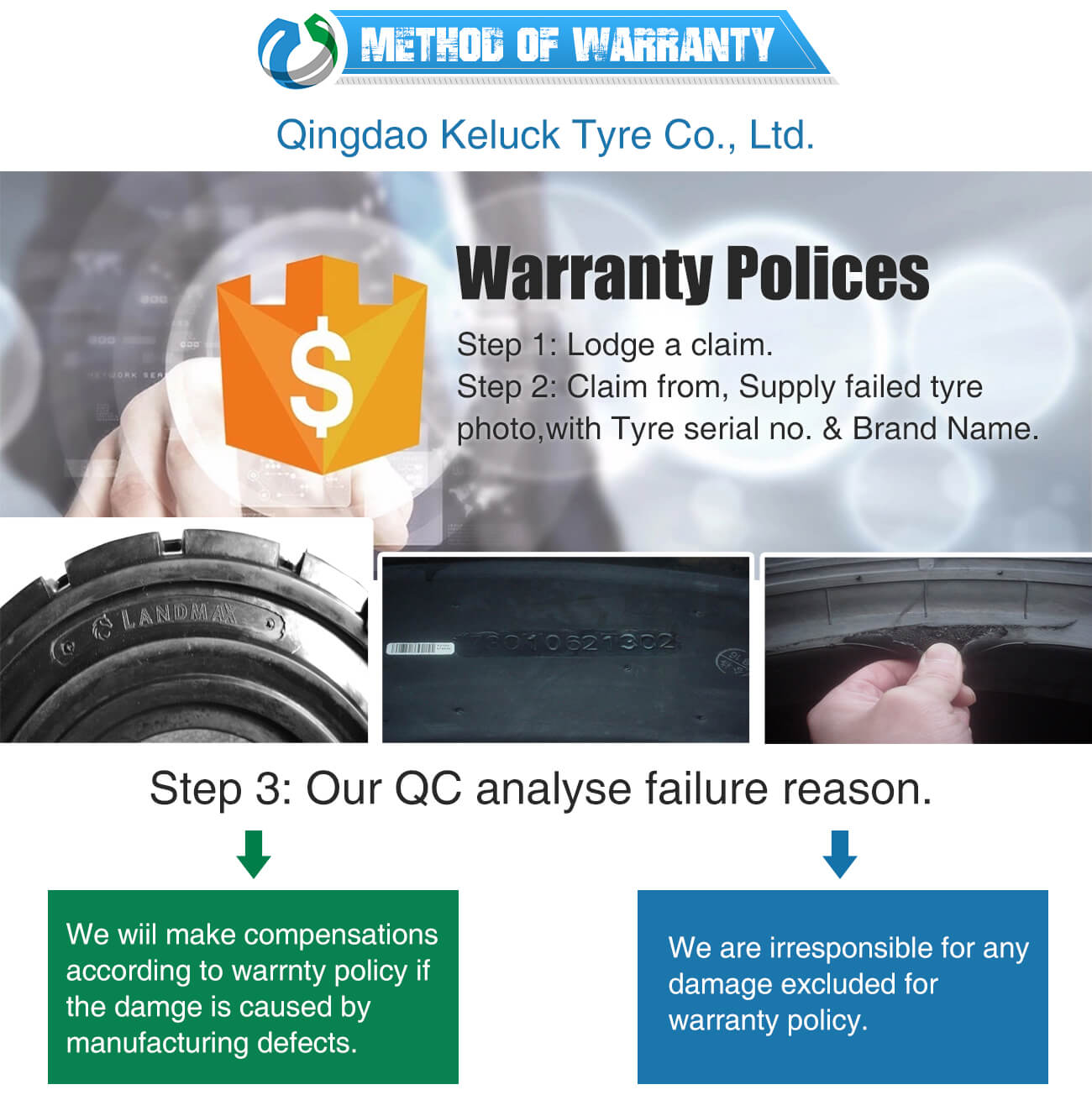

1. Eligibility

1) Tires must be purchased directly from Keluck Tyre Company (Indirect purchasers have to submit a claim to upper distributors).

2) Brand coverage: Keluck etc.

2. Time-Limit

1) Claims would be given to the tires that are in normal use according to specified conditions, the production date is within 2 years, tread pattern wear conforms to the regulations in claim policy, early damages appear due to manufacturing quality problems, and in accordance with the following rules.

2) There is no claim for tires of which production date is over 2 years.

II. Claim Standards

1. Compensation for Loss

1) Claims would be given to those tires with rest tread depth above 3mm and have quality problems;

2) Claims would be given to whatever damage caused by tire manufacturing quality problems.

2. Tire Quality Claim Identification Terms

2.1 Crown: Tire Tread

2.1.1 Crown separation: no trauma and impact, crown rubber and belt are separated.

2.1.2 Pattern groove cracking: pattern groove base of the tire without mechanical damage is cracked; the belt can be seen if serious.

2.1.3 Open joint: transverse rubber of crown is separated from rubber with a certain slope.

2.1.4 Tread rubber layer up partial tread rubber of crown fall off layer by layer, there is rubber powder or rubber block.

2.2 Shoulder: position from crown edge to curbing rib

2.2.1 Shoulder separation: shoulder rubber is separated from rubber, or rubber is separated from the belt, but no obvious protuberance, no scar on the surface of separation point, no tear, and no damage on the inner surface of the separation point.

2.2.2 Shoulder split: there is cracking between shoulder rubber and rubber in the peripheral direction, the surface of the cracking point is smooth, no trauma, with a certain slope and depth, the belt can be seen if serious.

2.2.3 Shoulder separation and blow out: there is no tear, mechanical damage, and crash, no damage on the inner surface of the tire inside.

2.3 Side part: position from shoulder curbing rib to chafer fitting line

2.3.1 Sidewall delaminating: side rubber is separated from the carcass, with no trauma on the outer surface.

2.3.2 Side bubble: there is an air bubble between the side rubber and carcass, which causes separation.

2.3.3 Side split: there is cracking between side rubber and rubber in the radial and circumferential direction, no damage by hard objects.

2.3.4 Side bloat: cord of radial tire is sparse; the side bloats in the radial direction during inflation.

2.4 Tire cavity: the inner surface between two bead toes

2.4.1 Separation: crown, the shoulder is separated from inner liner caused by some factors except overload.

2.4.2 Exposed cord: steel cord in the tire cavity is exposed partly, which causes some effects including assembly and usage of the inner tube, airtightness of tubeless tire.

2.4.3 Cavity separation: there is a separation between inner liners, which affects the airtightness of the tubeless tire.

2.4.4 Open joint of inner liner: joint of the inner liner is cracked, which affects airtightness of tubeless tire.

III. What Isn’t Covered

3.1 Damaged tires caused by abnormal usage and improper use in an early phase.

3.2 Tires as an unofficial product grade to sell (including the tire with unclear serial number: if the serial number is not clear before using, it should be given claims. Then punish the related department or principal after the tire returns; if the serial number is unclearly caused by wearing or disappeared with other causes after using, it cannot be given claims).

3.3 Retreaded tire.

3.4 Tires that the quality defects, identification (including size identification), ply rating and tire serial number is forged.

3.5 Tires repaired by the client (including there is/no causal relationship between repaired position and defect position).

3.6 Tires damaged by improper usage causing the following problems:

3.6.1 Crown blow out: crown blow out regularly.

3.6.2 Overloading shoulder separation: shoulder is separation in the circumferential direction, more than 1/4 perimeter.

3.6.3 Crown damage: rough tread rubber, block fall off.

3.6.4 Uneven wear: single side of the crown is wore quickly (the difference of pattern depth on both sides is over 3mm, or the residual pattern depth on uneven wear side is less than residual pattern depth for no claims).

3.6.5 Crown wears serious wear on the middle part of the crown.

3.6.6 Deformity wear: the crown is worn in the shape of a wave and saw tooth.

3.6.7 Zipper blows out: sidewall blow out in zipper-like circumferential direction or radial direction.

3.6.8 Wear bead toe: the chafer wear-out caused by insufficient pressure or unfit rim, chafer is exposed if serious; the carcass steel cord is cracked between bead toe and sidewall (bead break off).

3.6.9 Bead deformation: The bead area is damaged, or the steel cord of the bead is deformed.

3.6.10 Bead blow out: bead area blow out in circumferential direction caused by higher pressure, overload or crooked tire assembly.

3.6.11 Bead cracking: The bead area is cracked in circumferential direction caused by higher pressure, overload or crooked tire assembly.

3.6.12 Sidewall damage, carcass ford break or deformation caused by insufficient pressure.

3.6.13 Other problems are caused by improper usage.

3.6.14 Mechanical damage problem is caused by external factors.

3.6.14.1 Crown scratch: the crown is scratched trimly; the depth goes to the belt cord.

3.6.14.2 Crown puncturing: the crown is punctured by sharp objects (there is obvious mechanical damage mark, there is regular cut on wound), which causes the belt and carcass cord on puncture point to be cracked and separated, the tire would blow out if serious.

3.6.14.3 Shoulder trauma: shoulder is scratched or punctured by a barrier, rough wound, and no separation on the wound.

3.6.14.4 Split aperture: carcass is cracked in the radial direction, as a result, sidewall or crown run into sharp objects in the condition of high speed.

3.6.14.5 Side trauma: sidewall is cut or wore by sharp objects (cause the steel cord on the sidewall to be broken), no separation.

3.6.14.6 Bead damage: improper operation during tire assembly period, the bead chafer is broken; the bead lip of tubeless tire is broken.

3.7 Some problems beyond claims scope identified by plant technicians.

IV. Force Majeure

Even if we try our best, there are still problems with tires due to various reasons, so we could not control all the problems, and under the following circumstances, claims wouldn’t be offered:

4.1 Natural disasters, e.g. typhoon, floods, earthquakes, etc.

4.2 Government action, e.g. expropriation, requisition.

4.3 Social abnormal event, e.g. strike, riot.

V. Consumer Rights

Like our consumers, you have the right to be informed of your deserved rights and obligations. Due to the differences in claim policies among every distributor or wholesaler and the agents in different countries and regions, please consult and gain the best solutions!

VI. Claim Process

6.1 Consumers ask for the Claim Application Form and enclose the real product photos that show tire serial number, brand and the parts where problems exist. Consumers must have the purchase invoice and voucher (and the tire production date should be within 2 years).

6.2 When finishing filling out the Claim Application Form, send the related material (including copy/scanning piece of invoice voucher) to local agents by email or fax.

6.3 We would give preliminary judgment on the cause for the problem on the basis of material and photos submitted, and arrange agents or engineers to detect the tires that have problems if spot check is needed.

6.4 Give claim suggestions and provide reports according to analysis to tire problems and on the basis of claim standards.

6.5 Compensation procedure begins after consumers accept claim results and sign for confirmation. During this period consumers must provide the original copy of the purchase invoice when purchasing tires. There would be no claims without the original invoice.

VII. Safety Information for Tire Use

7.1 Check and adjust tire pressure at least once a month.

7.2 Check tires regularly to see if there is any abnormal wear.

7.3 Carry out tire rotation every 6,000 miles or on a regular period according to Consumer Manual.

7.4 Maintain the dynamic balance function of tires.

7.5 Calibrate steering and suspension system correctly.

7.6 Any piece of the tire mustn’t overload.

7.7 Avoid over-high temperature of tires.

7.8 Replace tires when needed.

7.9 Ensure that two or all tires be replaced together when installing tires.

7.10 Choose the appropriate tires according to cars and driving environment.

VIII. Our company reserves the right of final interpretation to other items not listed above and related issues!